UV Masterbatch

Price 200.0 INR/ Kilograms

UV Masterbatch Specification

- Shape

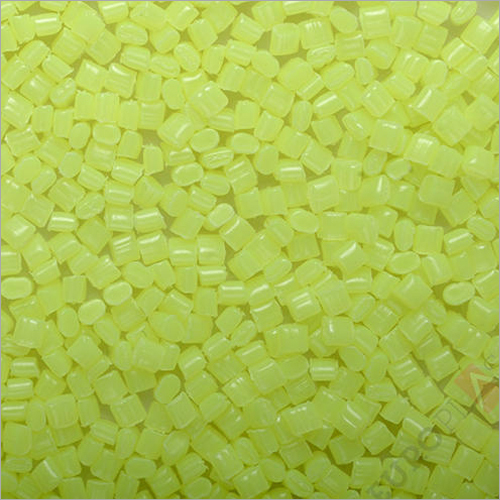

- Granules

- Carrier

- LLDPE

- Purity

- 100%

- Type

- Masterbatch

- Application

- Film, Blow Molding, Extrusion Molding, Injection Molding

UV Masterbatch Trade Information

- Minimum Order Quantity

- 100 Kilograms

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 5000 Kilograms Per Month

- Delivery Time

- 3-6 Week

- Main Domestic Market

- All India

About UV Masterbatch

UV Masterbatch

-

UV Protection Shields plastics from harmful UV radiation.

-

Extended Product Life Prevents discoloration, cracking, and degradation.

-

High Efficiency Works effectively at low dosages.

-

Excellent Dispersion Ensures uniform protection throughout the polymer.

-

Custom Formulations Tailored for outdoor and indoor applications.

-

Wide Polymer Compatibility Suitable for PE, PP, PET, PS, ABS, and more.

-

Consistency Assured Stable performance under long-term exposure.

Applications:

-

Outdoor furniture & automotive parts

-

Agricultural films & greenhouse covers

-

Packaging & industrial products

-

Fibers, textiles, and construction plastics

Advanced UV Protection for Plastics

Our UV Masterbatch is engineered to safeguard plastic products from the harmful effects of ultraviolet radiation. By integrating it during various molding processesincluding film, blow molding, extrusion, and injection moldingmanufacturers can ensure their products retain strength, color, and performance even after prolonged outdoor exposure. The masterbatch is supplied in high-purity granules, offering efficient dispersion and consistent protection.

Optimized Compatibility and Easy Processing

The masterbatch utilizes LLDPE as a carrier, making it highly compatible with a range of polyolefins and supporting seamless incorporation in diverse processing settings. Its granular shape ensures smooth blending and dispersement, resulting in even UV protection throughout the product. Ideal for manufacturers seeking reliable protection solutions manufactured in India.

FAQs of UV Masterbatch:

Q: How is UV Masterbatch applied during plastic processing?

A: UV Masterbatch is blended directly with raw polymer materials before or during the molding processes such as film, blow molding, extrusion, or injection molding. It disperses evenly, providing UV protection to the final product.Q: What benefits does using UV Masterbatch offer for plastic products?

A: Using UV Masterbatch enhances resistance to ultraviolet light, which helps prevent degradation, discoloration, and material breakdown. This extends product life and maintains appearance and mechanical properties in outdoor applications.Q: When should manufacturers consider using UV Masterbatch?

A: Manufacturers should use UV Masterbatch whenever plastic products are intended for environments with high exposure to sunlight or UV radiation. It is especially recommended for outdoor items, packaging, and agricultural films.Q: Where is this UV Masterbatch produced and supplied?

A: This UV Masterbatch is manufactured and supplied in India, ensuring availability for local and international customers seeking advanced UV protection for their plastic products.Q: What is the process for incorporating UV Masterbatch into manufacturing?

A: The masterbatch is introduced to the base polymer during standard compounding or molding processes. Its granular form enables efficient mixing and consistent dispersion, whether used in film, blow molding, extrusion, or injection molding.Q: What type of carrier is used in this UV Masterbatch?

A: The UV Masterbatch uses LLDPE (Linear Low-Density Polyethylene) as its carrier, which ensures compatibility with a range of polyolefin resins and smooth integration during processing.Q: How does the purity of 100% contribute to product effectiveness?

A: The 100% purity guarantees that the masterbatch contains no fillers or impurities, maximizing the concentration of UV-absorbing agents for optimal protection and reliable performance in end applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Special Masterbatch Category

Optical Brightener

Price 140.0 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Purity : 100%

Carrier : PP

Type : Masterbatch

Color : Green

Antiblock Masterbatch

Price 200.00 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Purity : 100%

Carrier : PE

Type : Masterbatch

Color : Blue

Antimicrobial Masterbatch

Price 400.0 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Purity : 100%

Carrier : PP

Type : Masterbatch

Color : Multicolor

Antioxidant Masterbatch

Price 200 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Purity : 100%

Carrier : PP

Type : Masterbatch

Color : Yellow

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry